Working Principle, Types, and Applications

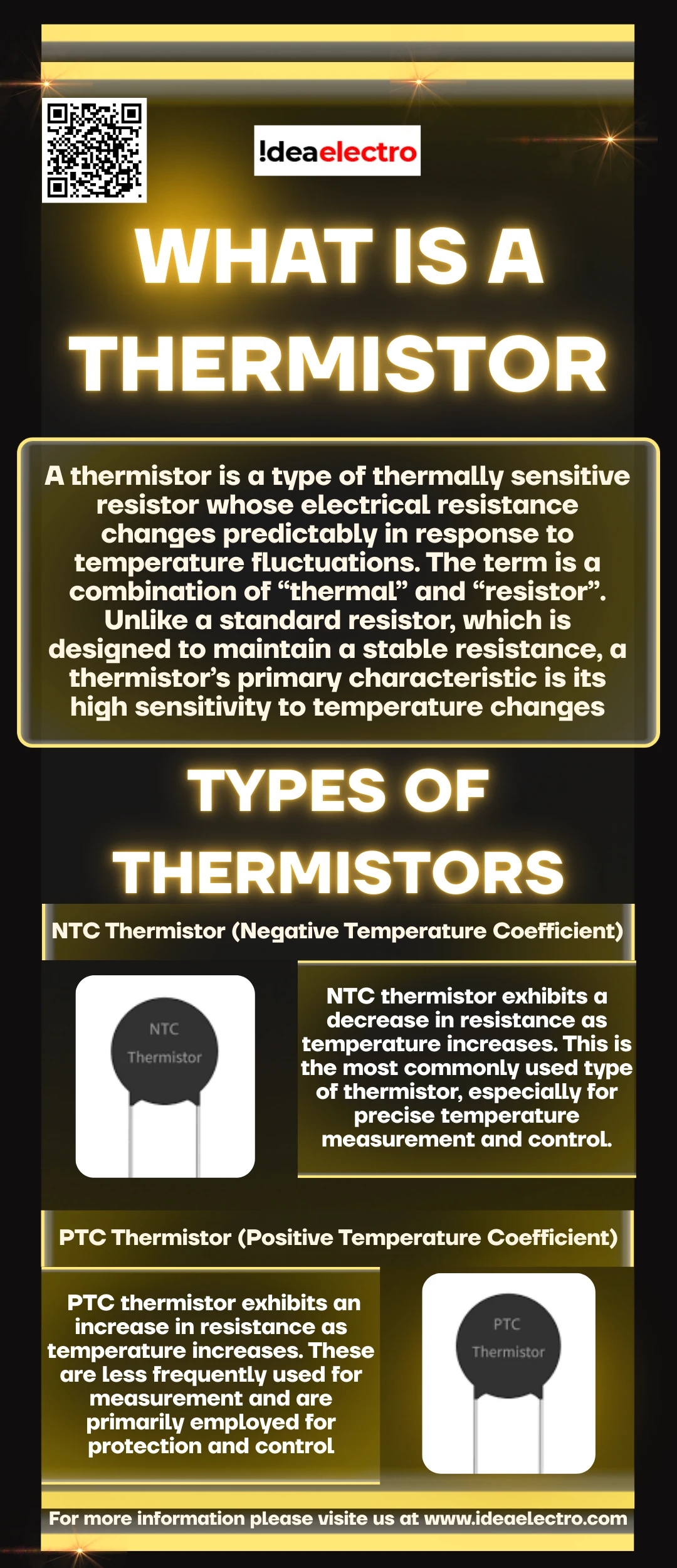

A thermistor is a type of thermally sensitive resistor whose electrical resistance changes predictably in response to temperature fluctuations. The term is a combination of “thermal” and “resistor”. Unlike a standard resistor, which is designed to maintain a stable resistance, a thermistor’s primary characteristic is its high sensitivity to temperature changes. This makes it not a component for limiting current but a sensor for measuring or reacting to thermal conditions. The relationship between its resistance and temperature can be either inverse or direct, leading to the two main classifications of thermistors, which are central to their function and application.

Working Principle of a Thermistor

The core operating principle of a thermistor is based on the behavior of semiconductor materials, typically metal oxides, from which it is constructed. As temperature affects the material, it alters the number of charge carriers available for conduction, thereby changing its electrical resistance.

- Increase in Temperature: In the more common Negative Temperature Coefficient (NTC) thermistor, heat energy provides electrons with sufficient energy to jump into the conduction band. This results in more charge carriers being available for current flow.

- Change in Resistance: With more charge carriers available, the material conducts electricity more easily. Consequently, the electrical resistance decreasesas temperature increases. For a Positive Temperature Coefficient (PTC) thermistor, the opposite occurs, and resistance increases with temperature.

- Electrical Signal Variation: This change in resistance is converted into a measurable electrical signal. A small, known bias current is passed through the thermistor, and the resulting voltage drop is measured. Since the resistance has changed, the voltage will change correspondingly, providing a signal that can be interpreted as a specific temperature.

A simple analogy is to imagine a road (the conductor) crowded with pedestrians (charge carriers). In an NTC thermistor, heating the material is like motivating the pedestrians to walk faster and spread out, reducing “resistance” to traffic flow and allowing cars (current) to move more freely.

Types of Thermistors

Thermistors are divided into two fundamental types based on the direction of their resistance change with temperature.

NTC Thermistor (Negative Temperature Coefficient)

An NTC thermistor exhibits a decrease in resistance as temperature increases. This is the most commonly used type of thermistor, especially for precise temperature measurement and control.

- Common Uses: Temperature sensing in digital thermometers, automotive coolant systems, household appliances, and battery management in consumer electronics.

- Key Characteristics: They offer high sensitivity, fast response times, and are cost-effective. Their response is non-linear, meaning the resistance-temperature curve is not a straight line, which requires mathematical modeling like the Steinhart-Hart equation for accurate calibration over wide ranges.

PTC Thermistor (Positive Temperature Coefficient)

A PTC thermistor exhibits an increase in resistance as temperature increases. These are less frequently used for measurement and are primarily employed for protection and control.

- Safety and Protection Roles: They act as self-resetting fuses for over-current protection or as heating elements in devices. When a fault causes excessive current, the PTC heats up, its resistance spikes, and it dramatically limits the current flow.

- Key Characteristics: They have a switching point (Curie temperature) at which resistance rises sharply. Common configurations include ceramic switching PTCs and polymer-based resettable fuses (PPTCs).

Thermistor Construction and Materials

Thermistors are primarily constructed from metal oxide ceramics, such as manganese, nickel, cobalt, copper, or iron oxides. These powders are combined with binders, pressed into a shape—such as a bead, disk, chip, or rod—and then sintered at high temperatures. The specific blend of materials determines the device’s resistance-temperature curve. This sensing element is then encapsulated for protection; epoxy coatings are used for general purposes, while glass encapsulation provides better durability, higher temperature tolerance (up to 300°C), and protection from humidity. The construction directly impacts performance: smaller bead-type thermistors have very fast response times but are more fragile, while larger disk or chip types are more robust and handle higher power.

Thermistor vs RTD vs Thermocouple

Selecting the right temperature sensor requires understanding the trade-offs between thermistors, Resistance Temperature Detectors (RTDs), and thermocouples. The following table summarizes key differences.

| Factor | Thermistor | RTD | Thermocouple |

| Accuracy | High (±0.1°C to ±0.5°C) in a narrow range | Very High (±0.1°C) over a wide range | Moderate (±1°C to ±2°C) |

| Temperature Range | Limited (-50°C to 150°C, up to 300°C for glass) | Wide (-200°C to 600°C or more) | Very Wide (-200°C to over 2000°C) |

| Response Time | Fast (due to small size) | Slower (due to larger size) | Fast to Very Fast |

| Cost | Low Cost | High Cost (platinum element) | Low to Moderate Cost |

| Typical Applications | Medical devices, consumer electronics, HVAC control | Industrial process control, scientific labs, food processing | Industrial furnaces, engine exhaust, high-temperature processes |

Choose a thermistor when your application requires high precision, fast response, and low cost within a moderate temperature range. They are ideal for monitoring a specific point, such as in electronic circuits or biomedical devices, rather than across extreme ranges.

Applications of Thermistors

Due to their sensitivity, size, and affordability, thermistors are ubiquitous in modern technology.

- Temperature Measurement and Control: This is the most common use, found in digital thermometers, thermostats, and climate control systems in buildings (HVAC).

- Over-Current Protection: PTC thermistors act as resettable fuses to protect circuits from fault currents in power supplies and consumer electronics.

- Battery Management Systems (BMS): They monitor cell temperature in batteries for smartphones, laptops, and electric vehicles to prevent overheating and optimize charging.

- Medical Devices: Their accuracy and small size make them suitable for patient monitoring systems, thermometers, and incubators.

- Automotive: Used to monitor engine coolant, oil, and cabin air temperature.

Advantages and Limitations of Thermistors

Advantages:

- High Sensitivity: They can detect very small temperature changes, offering excellent resolution within their optimal range.

- Low Cost: They are generally more economical than RTDs and competitive with thermocouples.

- Fast Response Time: Their small physical size allows them to react quickly to temperature changes.

Limitations:

- Limited Temperature Range: They are not suitable for extreme high-temperature environments where thermocouples excel.

- Non-Linear Resistance: Their output is a curve, not a straight line, requiring mathematical compensation or lookup tables for accurate measurement over a range.

- Calibration Requirements: While stable, achieving high accuracy may require calibration or the use of sensors with tight interchangeability tolerances.

How to Choose the Right Thermistor

Selecting the appropriate thermistor involves evaluating your application’s specific needs:

- Temperature Range Requirement: Determine the minimum and maximum temperatures the sensor will encounter. Ensure the thermistor’s operating range, typically -55°C to 150°C (extendable with special types), covers your needs.

- Accuracy Needs: Define the required precision (±0.1°C, ±0.5°C, etc.). Remember, accuracy is often highest within a limited band, such as ±50°C around a target temperature.

- Environmental Conditions: Consider exposure to moisture, chemicals, or mechanical stress. Choose appropriate packaging, such as epoxy coating, glass encapsulation, or a protective probe housing.

- Application Type: Decide if you need an NTC for measurement or a PTC for protection. For NTCs, select the correct resistance value (e.g., 10kΩ at 25°C) and resistance-temperature curve to match your system.

Conclusion

In summary, a thermistor is a fundamental and versatile temperature sensor that converts thermal information into an electrical resistance signal. Its high sensitivity, compact size, and low cost have cemented its importance across modern electronics, industrial control, and medical technology. For engineers and enthusiasts alike, understanding the working principles, types, and ideal applications of thermistors versus other sensors is crucial for designing effective and reliable systems where temperature is a key parameter