A transformer is a fundamental electrical device designed to transfer energy between circuits through electromagnetic induction. Its primary function is to increase or decrease alternating current (AC) voltage levels, a process essential for making electrical power usable across different stages of generation, transmission, and consumption. By enabling efficient voltage conversion, transformers serve as the critical link between high-voltage power lines and the safe, low-voltage electricity required in homes, offices, and industries. Without transformers, the safe and efficient distribution of electrical power over long distances and its adaptation for countless electronic devices would be impossible, underscoring their indispensable role in the modern electrical infrastructure.

History and Evolution of Transformers

The foundational principle behind transformers, electromagnetic induction, was discovered independently by Michael Faraday and Joseph Henry in the 1830s. However, the first practical transformers for power systems emerged decades later. Key developments included early induction coils and the work of the Ganz Company in Hungary in the late 1870s. The transformative moment came in 1886 when William Stanley, working for Westinghouse, built and demonstrated the first reliable commercial AC transformer system in Great Barrington, Massachusetts. This system effectively proved the feasibility of using transformers for AC power distribution. Later innovations, such as Mikhail Dolivo-Dobrovolsky’s development of the first three-phase transformer in 1889, were pivotal for creating the efficient, high-power electrical grids we rely on today. The evolution from Stanley’s early designs to modern, highly efficient units has been driven by continuous improvements in core materials, winding techniques, and cooling systems, enabling the massive scale of contemporary global power networks.

Basic Working Principle of a Transformer

The operation of a transformer is governed by Faraday’s Law of Induction, which states that a changing magnetic field within a coil of wire will induce a voltage across its ends. A transformer utilizes this principle by having two coils of wire, known as windings, placed in close proximity around a common magnetic core. When an alternating current (AC) flows through the primary winding, it creates a continuously changing magnetic field. This changing magnetic flux circulates through the core and passes through the secondary winding, thereby inducing an alternating voltage in it. The key to voltage conversion lies in the ratio of the number of turns in each coil. A fundamental rule is that the ratio of the primary voltage to the secondary voltage is equal to the ratio of the primary turns to the secondary turns.

- Primary Coil: This winding receives the input AC voltagefrom the electrical source.

- Secondary Coil: This winding delivers the output voltageto the connected load.

- Core: Typically made from laminated steel, the core provides a low-reluctance pathfor the magnetic flux, strengthening the magnetic coupling between the two windings and ensuring efficient energy transfer.

- Turns Ratio: This is the cornerstone of transformer operation. If the secondary winding has more turnsthan the primary, the output voltage is higher (step-up). If it has fewer turns, the output voltage is lower (step-down).

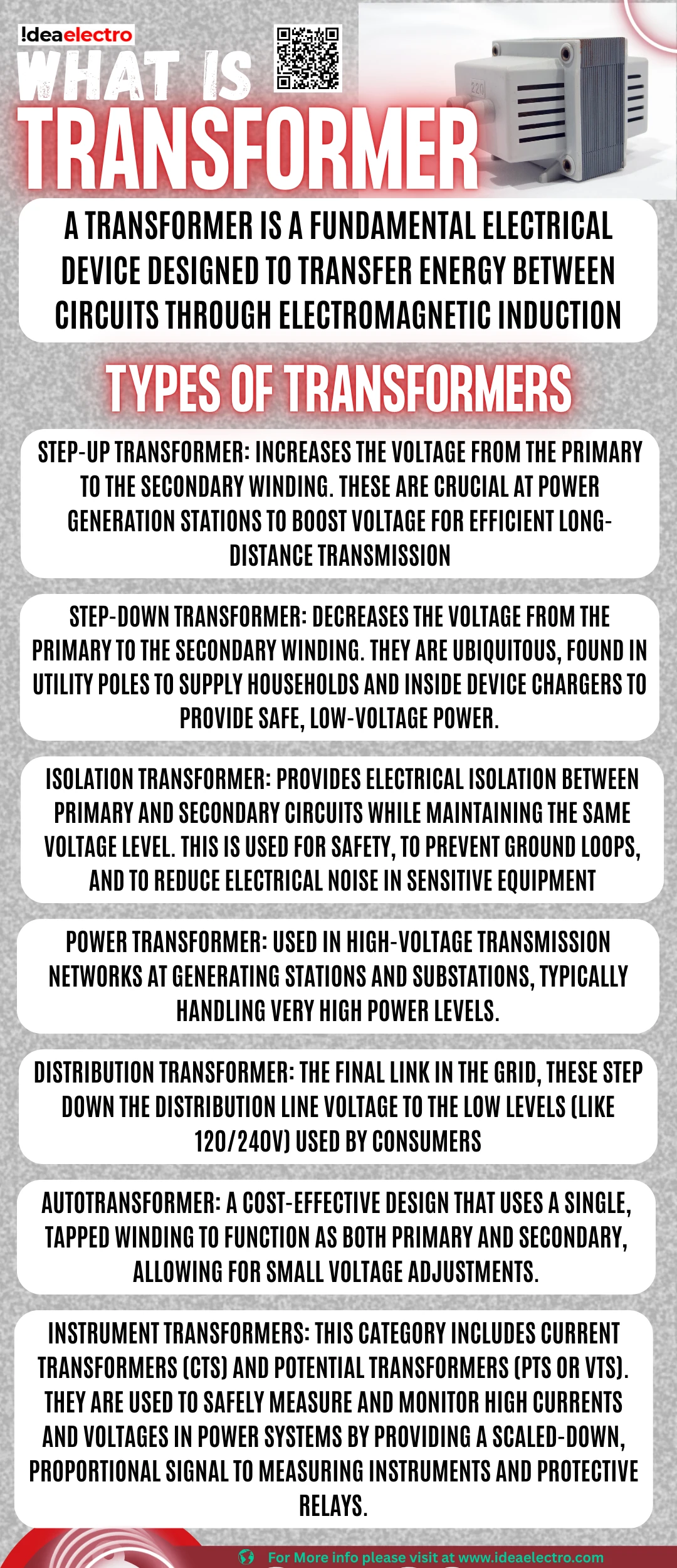

Types of Transformers

Transformers are manufactured in various configurations to serve specific roles within electrical and electronic systems. The most basic classification is based on their function in changing voltage levels.

- Step-Up Transformer: Increases the voltage from the primary to the secondary winding. These are crucial at power generation stations to boost voltage for efficient long-distance transmission.

- Step-Down Transformer: Decreases the voltage from the primary to the secondary winding. They are ubiquitous, found in utility poles to supply households and inside device chargers to provide safe, low-voltage power.

- Isolation Transformer: Provides electrical isolationbetween primary and secondary circuits while maintaining the same voltage level. This is used for safety, to prevent ground loops, and to reduce electrical noise in sensitive equipment.

- Power Transformer: Used in high-voltage transmission networks at generating stations and substations, typically handling very high power levels.

- Distribution Transformer: The final link in the grid, these step down the distribution line voltage to the low levels (like 120/240V) used by consumers.

- Autotransformer: A cost-effective design that uses a single, tapped windingto function as both primary and secondary, allowing for small voltage adjustments.

- Instrument Transformers: This category includes Current Transformers (CTs)and Potential Transformers (PTs or VTs). They are used to safely measure and monitor high currents and voltages in power systems by providing a scaled-down, proportional signal to measuring instruments and protective relays.

Key Components of a Transformer

The reliable operation of a transformer depends on the integration of several key physical components, each with a dedicated role. At its heart are the core and the windings, which form the active part responsible for energy transfer. Surrounding these are structural and auxiliary systems that ensure longevity, safety, and efficiency.

The following table outlines the primary components and their functions:

| Component | Description |

| Core | Constructed from laminated silicon steel sheets, it provides a controlled magnetic path for flux, maximizing coupling between windings and minimizing energy losses. |

| Primary Winding | The coil of wire that receives input power from the AC source. The number of turns determines its voltage relationship with the secondary winding. |

| Secondary Winding | The coil of wire that delivers output power to the load. Its number of turns relative to the primary defines whether the transformer steps voltage up or down. |

| Tank/Enclosure | A robust steel or aluminum container that houses and protects the internal core and windings from environmental damage. |

| Insulation | Critical materials like paper, pressboard, and oil that prevent electrical shorts between windings and between windings and the grounded core/tank. |

| Cooling System | A mechanism to maintain safe operating temperature. This can range from simple radiator fins for oil-filled transformers to fans and pumps for larger units. |

Applications of Transformers

Transformers are integral to modern life, with applications spanning from massive grid infrastructure to small consumer electronics. Their ability to manipulate voltage and provide isolation makes them versatile components in numerous fields.

- Power Transmission and Distribution: This is their most critical application. Step-up transformers enable efficient long-distance transmission, while step-down transformers make power safe for end-use in residential, commercial, and industrial settings.

- Electronic Chargers and Adapters: Virtually every device that plugs into a wall outlet contains a small step-down transformer(or a switched-mode power supply that uses a high-frequency transformer) to convert mains voltage to the low DC voltage required by the circuitry.

- Industrial Machines and Equipment: Factories use transformers to supply appropriate voltages for heavy machinery, motors, control circuits, and welding equipment.

- Audio Systems: Specialized audio transformersare used for impedance matching between different components (like microphones and amplifiers) to ensure maximum power transfer and signal fidelity.

- Renewable Energy Systems: Solar inverters and wind turbine generators use transformers to interface with the power grid, stepping up their generated voltage to match distribution levels.

- High-Voltage Testing Labs: Specialized transformers, including potential transformers (PTs), are essential for safely measuring and testing high-voltage equipment.

Advantages of Transformers

Transformers are a cornerstone of electrical engineering due to their compelling advantages, which explain their enduring and universal use.

- High Efficiency: Modern transformers are exceptionally efficient, typically between 95-99%, meaning very little energy is lost as heat during the voltage conversion process.

- Long Lifespan: With proper maintenance, transformers can operate reliably for decades, making them a durable infrastructure investment.

- Stable Voltage Regulation: Features like tap changersallow for the adjustment of output voltage to compensate for fluctuations in the supply, ensuring a stable voltage to the load.

- Low Maintenance: As static devices with no moving parts (except for cooling fans in some models), they require relatively minimal maintenance.

- Essential for Safe Power Distribution: By enabling the use of high-voltage for low-loss transmission and safe, low-voltage for consumption, transformers are fundamental to public safety and grid reliability.

Limitations of Transformers

Despite their advantages, transformers have inherent limitations that must be considered in system design.

- They operate only with Alternating Current (AC)and cannot function with Direct Current (DC), as a steady current does not produce a changing magnetic field.

- For high-power applications, they can be bulky and heavy, especially oil-filled power transformers, due to the large core and winding materials required.

- Energy lossesoccur in the form of heat from copper losses (in the windings) and core losses (hysteresis and eddy currents), requiring effective cooling systems.

- Large units often require proper cooling(oil, air, or water-based) and periodic maintenance, such as oil testing and filtration, to ensure longevity.

Conclusion

In summary, a transformer is a static electromagnetic device that uses the principle of mutual induction to efficiently change AC voltage and current levels while transferring power between isolated circuits. From their historical roots in the 19th century to their central role in today’s smart grids and renewable energy networks, transformers have been, and continue to be, indispensable to electrical power systems. As technology evolves, transformers are also adapting, with advancements in materials like amorphous metals and designs for power electronics pushing the boundaries of efficiency, size, and functionality, ensuring they will remain vital components in the electrified future.